TE Wire & Cable offers extensive calibration services to assure that our customers’ critical accuracy requirements are met. All calibrations are performed in our in-house calibration laboratory, which is directly traceable to NIST (National Institute for Standards and Technology). All thermocouple wire is carefully calibrated, selected and matched to meet or exceed ASTM and ANSI initial calibration tolerance requirements (see below).

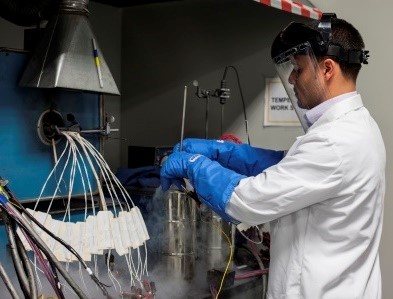

Cryogenic Calibration

Calibration temperature capabilities are cryogenic –320°F (-196°C) and at any point from a low temperature of -110F (-79C) through an upper temperature of 2400°F (1316°C). Certified calibration test reports are available showing temperature deviations, correction factors or actual temperature readings.

Calibration reference standards, directly traceable to NIST, include base metal, Type S platinum, Type B platinum, 25 OHM platinum resistance thermometer and freeze point cells.

TE Wire & Cable’s calibration laboratory is ISO 9001:2015 certified, and conforms to the requirements of MIL STD-45662A, ANSI/NCSL Z540-1-1994, AMS 2750, ASTM E220, ASTM E207.

Products can be supplied to meet the calibration standards of ASTM E230, BAC 5621, ST 2155 and other customer special accuracy requirements.

TE Wire & Cable’s calibration laboratory is also A2LA accredited to ISO/IEC 17025:2017, Certificate Number 2792.01.

In addition to wire, TE Wire & Cable offers calibration of thermocouple assemblies, sensors and RTD’s.

Table 1

Initial Calibration Tolerances Per ASTM E230 and ANSI MC96.1

| Tolerance-Reference Junction 32F (0C) |

|||||

|---|---|---|---|---|---|

| Thermocouple Type | Temperature Range F (C) | Grade Designation | Standard Grade Limits F (C) whichever is greater | Grade Designation | Special Grade Limits F (C) whichever is greater |

| Thermocouple Wire | |||||

| T | 32 (0) to 700 (370) | T | ±1.8 (1) or ±0.75% | TT | ±0.9 (0.5) or .04% |

| J | 32 (0) to 1400 (760) | J | ±4 (2.2) or ±0.75% | JJ | ±2 (1.1) or 0.4% |

| E | 32 (0) to 1600 (870) | E | ±3.1 (1.7) or ±0.50% | EE | ±1.8 (1) or 0.4% |

| K or N | 32 (0) to 2300 (1260) | K or N | ±4 (2.2) or ±0.75% | KK or NN | ±2 (1.1) or 0.4% |

| T* | -328 (-200) to 32 (0) | T | ±1.8(1) or ±1.5% | TT | ±0.9 (0.5) or 0.8%** |

| E* | -328 (-200) to 32 (0) | E | ±3.1(1.7) or ±1% | EE | ±1.8 (1) or 0.5%** |

| K* | -328 (-200) to 32 (0) | K | ±4(2.2) or ±2% | KK | ** |

| Extension Wire | |||||

| TX | 32 (0) to 212 (100) | TX | ±1.8 (1) | TTX | ±0.9 (0.5) |

| JX | 32 (0) to 400 (200) | JX | ±4 (2.2) | JJX | ±2 (1.1) |

| EX | 32 (0) to 400 (200) | EX | ±3.1 (1.7) | EEX | ±1.8 (1) |

| KX or NX | 32 (0) to 400 (200) | KX or NX | ±4 (2.2) | KKX or NNX | ±2 (1.1) |

| RX or SX | 32 (0) to 400 (200) | RX or SX | ±9 (5) | ||

| BX | 32 (0) to 212 (100) | BX*** | ±7.6 (4.2) | ||

| BX | 32 (0) to 400 (200) | BX ALLOY*** | ±6.7 (3.7) | ||

* Thermocouple material is normally supplied to meet tolerances above 0C (32F).

If material is required to meet tolerances below 0C (32F), the purchase order

must so state. Special selection of material is required.

** Suggested initial calibration tolerance. Requirements should be discussed

between purchaser and supplier before calibration testing.

*** Copper vs. copper can be used as an extension for Type B thermocouples

if the transition is below 100C (212F). Above 100C (212F), PCLW30-6 alloy should be used as the positive extension wire.

Learn More:

- Can different thermocouple wire calibration types be used in the same circuit?

- Everything You Wanted to Know About Thermocouple Theory and Chemistry (but Were Afraid to Ask)

- How to Control Noise in Instrumentation Circuits (Part 1)

- How to Control “Noise” in Instrumentation Circuits (Part 2)

- 3 Basic Steps to Selecting the Right Thermocouple Wire for Your Application

- What do the thermocouple wire color codes mean?